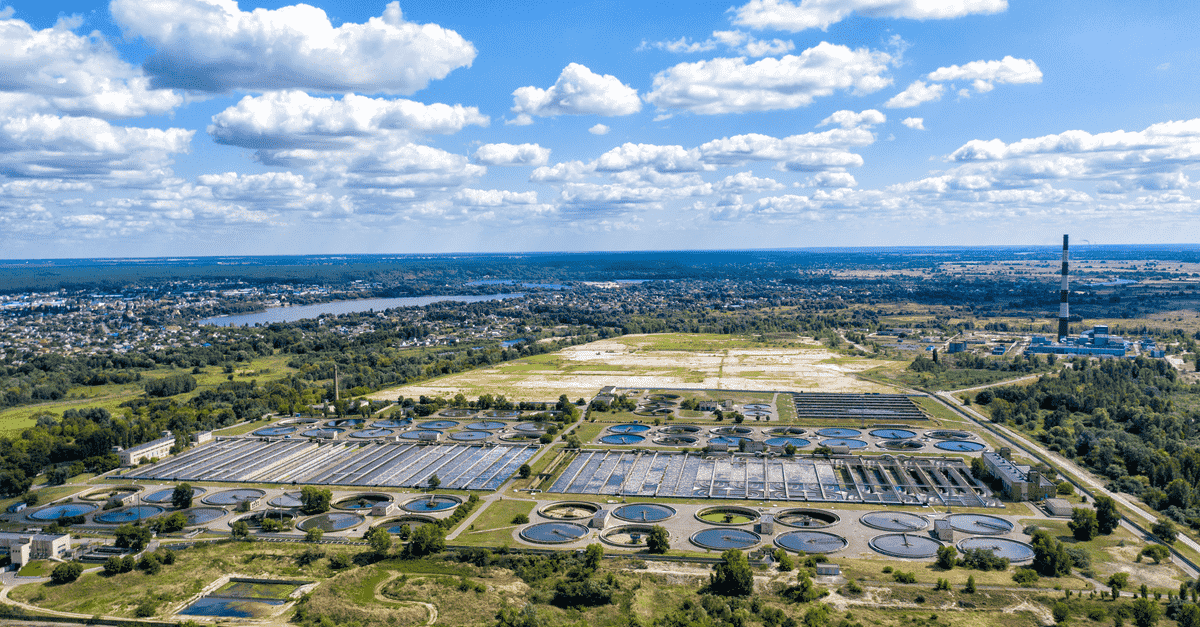

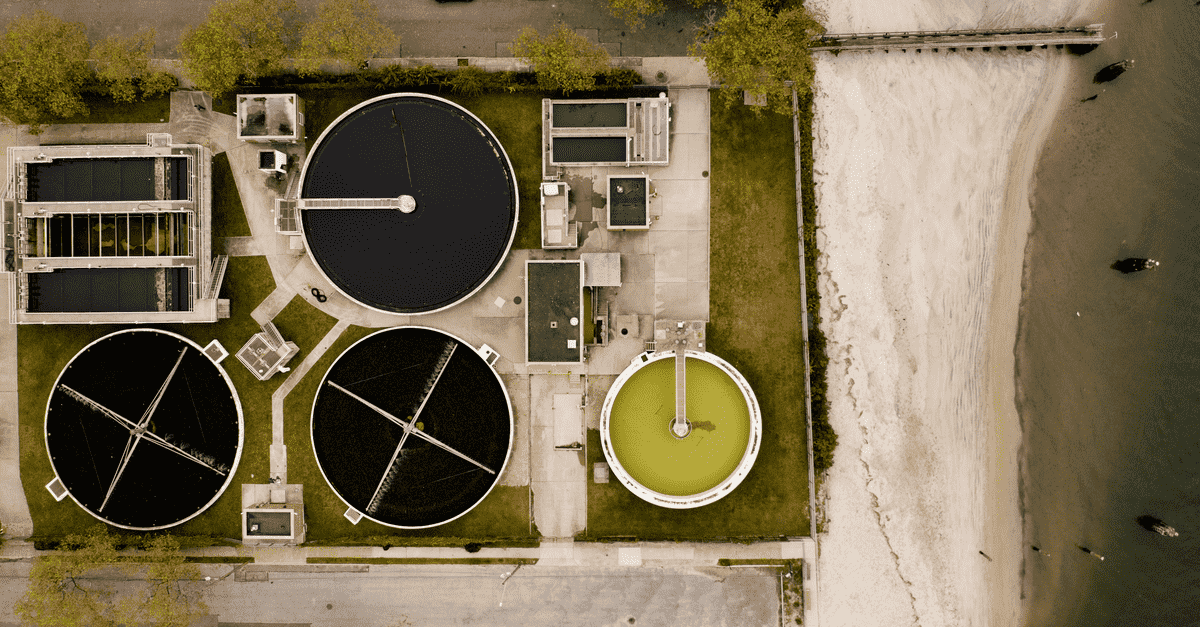

SNF Italia specializes in water chemistry. Our markets are driven by the increasing scarcity of natural resources such as water, oil, gas, and minerals. Most of our product applications either treat and recycle water, or minimize water consumption. In addition, we help our customers reduce their energy consumption and therefore their carbon footprint. As a global leader in manufacturing water-soluble polymers, SNF has developed a range of more than 1,000 products that help to preserve natural resources, encourage recycling, and improve industrial process efficiencies. SNF polymers have several complementary functionalities: flocculation, coagulation, rheology modification, and friction reduction.

SECTORS:

Drilling, Mining, Dredging, Papermills, Quarries and Marbles, Drinking Water

APPLICATIONS:

Flotation, Sedimentation, Thickening, Sludge Dewatering

DRYFLOC™ powder anionic polyelectrolytes come in the form of free-flowing and highly hygroscopic granules. The range includes a range of products ranging from low ionicity to very high charge. The products differ in charge class, ranging from molecular weights of a few million up to 20 and over millions of Daltons. The wide differentiation in anionicity and molecular weights allows the selection of the most suitable product for the characteristics of the wastewater and sludge to be treated.

Anionic polyelectrolytes are widely used in the following applications:

- TANNERIES

- PRODUCTION OF DRINKING WATER

- PROCESSING OF MARBLE AND GRANITE

- STEEL INDUSTRY

- EXCAVATED EARTH AND ROCKS

- GALVANIC

- PAPER PRODUCTION

- FOOD

- DREDGING OF PORT AREAS

- FARMING

- DRILLING MUDS

- WASHING OF SAND AND GRAVEL FROM QUARRYING

- PHYSICO-CHEMICAL TREATMENTS OF BOTH INDUSTRIAL AND URBAN WASTEWATER

SECTORS:

Drilling, Mining, Dredging, Papermills, Quarries, and Marbles, Drinking Water

APPLICATIONS:

Flotation, Sedimentation, Thickening, Sludge Dewatering

The DRYFLOC™ EM series anionic polyelectrolytes in emulsion are in the form of a milky white liquid.

The range includes a range of products ranging from low ionicity to very high charge.

The products differ in charge class, ranging from molecular weights of a few million up to 20 and over millions of Daltons.

The wide differentiation in anionicity and molecular weights allows the selection of the most suitable product for the characteristics of the wastewater and sludge to be treated.

Anionic polyelectrolytes are widely used in the following applications:

- TANNERIES

- PRODUCTION OF DRINKING WATER

- PROCESSING OF MARBLE AND GRANITE

- STEEL INDUSTRY

- EXCAVATED EARTH AND ROCKS

- GALVANIC

- PAPER PRODUCTION

- FOOD

- DREDGING OF PORT AREAS

- FARMING

- DRILLING MUDS

- WASHING OF SAND AND GRAVEL FROM QUARRYING

- PHYSICO-CHEMICAL TREATMENTS OF BOTH INDUSTRIAL AND URBAN WASTEWATER

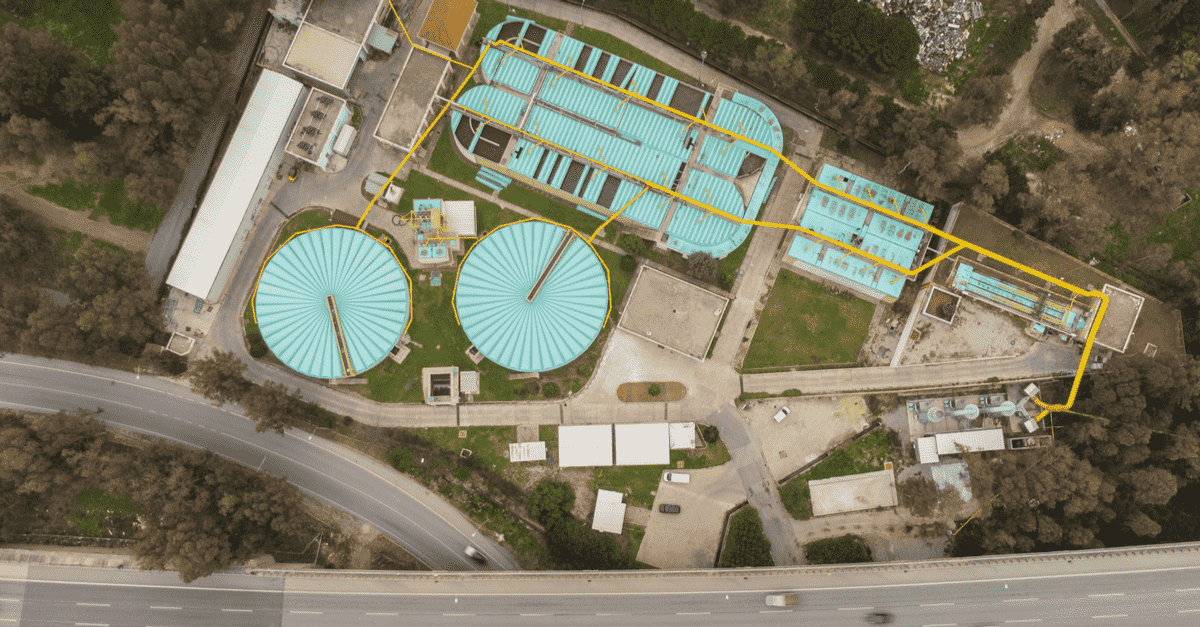

SECTORS:

Municipal, Paper, Petrochemicals, Livestock, Food, Tanning, Textiles

APPLICATIONS:

Flotation, Sedimentation, Thickening, Sludge Dewatering

DRYFLOC™ cationic polyelectrolytes in powder form are free-flowing and highly hygroscopic granules.

The range includes a range of products ranging from low ionicity to very high charge.

The products differ in charge class, ranging from molecular weights of a few million up to 20 and over millions of Daltons.

The wide differentiation in cationicity and molecular weights allows for selecting the most suitable product for the characteristics of the wastewater and sludge to be treated.

Cationic polyelectrolytes are widely used in the following applications:

- AEROBIC AND ANAEROBIC SLUDGE DEWATERING

- BIOLOGICAL SLUDGE THICKENING

- TANNERIES

- PAPER PRODUCTION

- FOOD

- ANIMAL HUSBANDRY

- PETROCHEMICALS

- BIOMASS ENERGY

- DREDGING OF PORT AREAS

- TEXTILES

- DRINKING WATER

SECTORS:

Municipal, Paper, Petrochemicals, Livestock, Food, Tanning, Textiles

APPLICATIONS:

Flotation, Sedimentation, Thickening, Sludge Dewatering

DRYFLOC™ EM series cationic polyelectrolytes in emulsion come in the form of a milky white liquid.

The range includes a range of products ranging from low ionicity to very high charge and with different types of molecular chains which give different flocculation behaviors and resistance to the mechanical stress of the formed flakes.

The products differ in charge class, ranging from molecular weights of a few million up to 20 and over millions of Daltons.

The wide differentiation in cationicity and molecular weights allows the selection of the most suitable product for the characteristics of the wastewater and sludge to be treated.

Cationic polyelectrolytes are widely used in the following applications:

- CENTRIFUGATION OF AEROBIC AND ANAEROBIC SLUDGE

- BIOLOGICAL SLUDGE THICKENING

- TANNERIES

- PAPER PRODUCTION

- FOOD

- FARMING

- PETROCHEMICAL

- BIOMASS ENERGY

- DREDGING OF PORT AREAS

- TEXTILES

SECTORS:

Municipal, Paper, Petrochemicals, Livestock, Food, Tanning, Textiles

APPLICATIONS:

Flotation, Sedimentation, Thickening, Sludge Dewatering

The DRYFLOC™ CO Series organic coagulants are liquid copolymers.

They are obtained by condensation of primary and secondary amines characterized by a positive ionic charge with a medium-low molecular weight between 10,000 and 1,000,000 Daltons.

They are used in treatments in the aqueous phase, as coagulants of colloidal particles in solid suspension, thus favoring the clarification-flocculation process.

In addition to sedimentation processes, they can also be used in flotation or continuous filtration of filter materials.

The fields of application are:

- PETROCHEMICALS

- PRODUCTION OF DRINKING WATER

- FARMING

- FOOD

- DRILLING

- PAPER

- TEXTILES

- DREDGING OF PORT AREAS

- TANNING

- WASHING OF SAND AND GRAVEL FROM QUARRYING

SECTORS:

Textiles, Tanning, Municipal, Food, Livestock, Agri-food, Pharmaceuticals

APPLICATIONS:

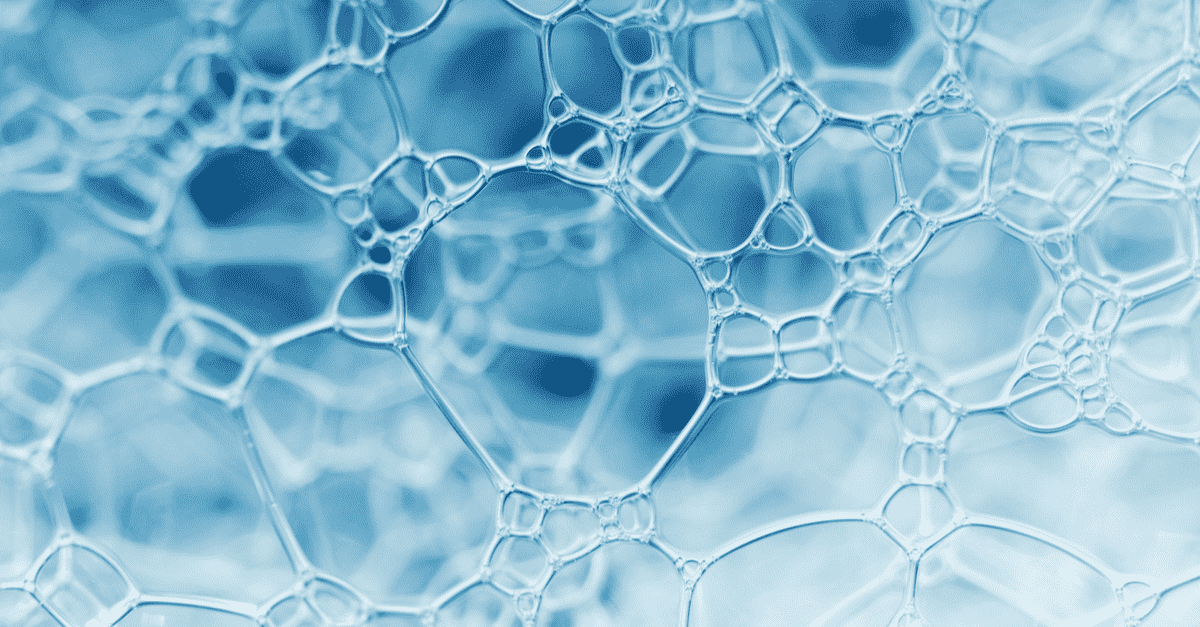

Abatement and control of foams

SNF’s range of defoamers consists of silicone, non-silicone, and water-based products. They find application in the treatment of wastewater of any industrial activity and within production processes, especially in the agri-food and pharmaceutical sectors.

In wastewater treatment, light foam is not usually a problem, but a massive presence can seriously complicate the functionality of many plants.

The excess foam can cause the wrong reading of the measurement systems of parameters such as temperature, pH, and level, all this can lead to incorrect management of the dosage and reaction of the reagents, consequently leading to a loss of yield of the treatment.

Furthermore, the presence of foam in the sedimentation tanks causes the mud flakes to be dragged to the surface, thus worsening the quality of the effluent.

The problem can be addressed both by inhibiting the formation and by controlling the presence of foams in the system, depending on the case, antifoams with different specificities will be used.

As far as the agri-food and pharmaceutical sectors are concerned, the formation of foam can instead cause a loss of productivity and quality of the finished product.

The range of defoamers intended for these sectors includes high-quality products, with KOSHER, HALAL, and FDA approval, suitable for the abatement and control of fermentation and food production foams (yeast, starch, etc. )

They are used in the following sectors:

- TEXTILES

- TANNERIES

- MUNICIPALITIES

- FOOD

- AGRI-FOOD

- PHARMACEUTICALS

- ZOOTECHNICS

SECTORS:

Textiles, Tanning, Chemicals, Municipal Water Treatment

APPLICATIONS:

Removal of residual color of waste water

The DEC series represents a range of liquid cation copolymers. In the presence of particularly colored wastewater, it is possible to remove the color and its pollutant contribution by flocculation.

Their easy application makes them particularly suitable for both biological and chemical-physical purification plants.

The technical assistance service is able to indicate both the correct point of application and the dosage of the recommended product in order to obtain the best result in terms of clarity and reduction of the organic load.

The main fields of application are:

- TEXTILES

- TANNERIES

- CHEMIST

- MUNICIPALITIES

- FOOD

- FARMING

- ZOOTECHNY

SECTORS:

Municipal, Petrochemicals, Livestock, Food, Tanning, Textiles

APPLICATIONS:

Increase in bacterial degradation

FLOZYME consists of selected mixtures of Enzymes and Bacteria.

They are used both to increase bacterial degradation in biological civil and industrial wastewater treatment plants and to control unpleasant odors that are produced in the water and sludge treatment cycle.

A typical application of FLOZYME:

• Biological priming of a new plant.

• Recovery of post-shock biological function due to production overloads, and accidental discharges of toxic substances.

• Control of the formation of biological foams due for example to Michrotrix Particle.

• Inhibitions of the formation of bad smells due both to the presence of greasy or oily substances and to the unwanted triggering of biological reactions that develop malodorous substances.

FLOZYME products are widely used in the following applications:

- TEXTILES

- AGRI-FOOD

- CHEMIST

- PETROCHEMICALS

- PHARMACEUTICALS

- TANNERIES

- MUNICIPALITIES

- COMPOSTING

- ANAEROBIC DIGESTION

SECTORS:

Agriculture, Drilling, Landscaping

APPLICATIONS:

Increase water reserve available in the substrate

AQUASORB™ superabsorbents are copolymers of anionic acrylamide crosslinked with potassium acrylate making them insoluble in water.

In fact, incorporated into a soil or substrate, they have the ability to absorb large quantities of water and nutrients dissolved in it and unlike most water-retaining products, AQUASORB™ has the property of releasing it easily based on the demand of the apparatus. radical concerned.

AQUASORB™ is able to absorb water up to 400 times its weight, acting as a water reserve in arid climates or where there is a shortage of rain, responding directly to water savings, energy, and maintenance costs.

The range has various particle sizes depending on the final application.

AQUASORB™ is widely used in the following applications:

- HORTICULTURE

- LARGE-SCALE AGRICULTURE

- HYDROSEEDING

- FLORICULTURE

- PLANTATIONS

- NURSERIES

- PERFORATIONS

- CIVIL ENGINEERING

- FIRE BREAK BARRIERS

- WATER BARRIERS

SECTORS:

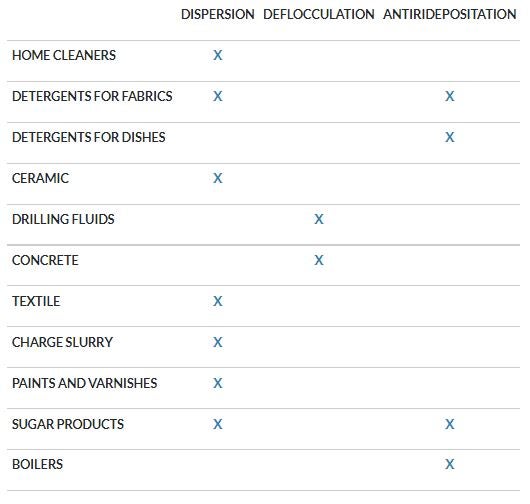

Cleaning, Ceramics, Cement, Papermills, Perforation, Textiles

APPLICATIONS:

Dispersants, Deflocculants, Anti-redeposition agents

FLOSPERSE™ polyacrylates are available in both liquid and powder forms.

They can be adapted and customized according to customer needs and include both homopolymers and copolymers of different monomers and different levels of molecular weights (2,000 to 100,000 Daltons).

Their dispersing, deflocculating, and anti-redepositing action allows various application possibilities:

SECTORS:

Cleaning, Cement, Perforation, Dustproof, Cosmetics

APPLICATIONS:

Rheological viscosity modifiers

The rheological modifiers of SNF are viscosifiers in emulsion, liquid, or powder.=

Depending on the application we can supply products to obtain both opaque and neutral solutions depending on the application purpose of the final formulation.

The range of products differs into 4 macro groups:

- FLOCARE™: Anionic and Cationic Polymers in powder or liquid form used in body care products.

- FLOSOFT™: Cationic Polymers in powder or emulsion used for home care and laundry.

- FLOGEL™: Anionic Polymers and Carbomer in powder or emulsion used in-home care products.

- FLOSET™: Liquid or emulsion anionic polymers used as anti-dust for roads, conveyor belts, and heaps of storage material.

The main sectors of use are:

- BODY CLEANSING

- HOUSE CLEANING

- LAUNDRY SOFTENERS

- MINING AND QUARRYING SECTORS

- COSMETICS

- PERFORATIONS

- CEMENTITIOUS

- SHAMPOOS

- HAIR GELS

SECTORS:

Tanning, Municipal, Chemicals and Petrochemicals, Food, Livestock

APPLICATIONS:

Odor control

The ODORFLO™ line includes both covering deodorizing and neutralizing products.

Odors are generally associated with the degradation processes of organic substances that lead to the formation of substances such as hydrogen sulfide (H2S), ammonia (NH3), mercaptans (RSH), and amines (RNH2 or RNH).

Identifying the cause and source of the bad smell is a priority:

- Is it a safety problem for the operators?

- Does it prevent the normal course of work?

- Is it a problem for the neighborhood?

In response to these questions, the most suitable product from the ODORFLO™ range to solve the problem can be applied.

The fields of application are as follows:

- TANNING

- MUNICIPALITIES

- CHEMISTRY

- PETROCHEMICALS

- FOOD

- ANIMAL HUSBANDRY

SECTORS:

Waste-to-energy, Steel, Galvanic

APPLICATIONS:

Chelation of heavy metals

METALSORB™ products are completely soluble in water and ready to use.

Reacting with various heavy metals such as Mercury, Cadmium, Lead, Copper, and Zinc, they form insoluble precipitates that can easily settle with the help of DRYFLOC™ polymers.

The formation of a well-thickened sludge minimizes disposal costs.

The wide molecular architecture allows the formation of flakes suitable for any type of plant.

The products can be applied in a wide pH range between 4 and 9.

The fields of application are:

- WASTE-TO-ENERGY

- IRON AND STEEL INDUSTRY

- GALVANIC

- ELECTRONICS

- TANNING

- ELECTRODEPOSITION

- AUTOMOTIVE

SECTORS:

Drilling, Bituminous Shale

APPLICATIONS:

Drilling, Exploitation, and Recovery of Oil Fields

SNF is active in the OIL & GAS field with a dedicated team (EOR).

SNF is able to design and develop plants and products for tertiary oil recovery.

To find out more, visit the website: oil.snf.com